Copper alloys are integral to machinery, offering a diverse range of properties that enhance performance and longevity.

Brass, a copper-zinc alloy, finds application in gears, valves, and fittings, combining strength, machinability, and corrosion resistance.

Bronze, a copper-tin alloy, is widely used in the manufacturing of wear-resistant components like bushings and bearings due to its strength and corrosion resistance.

Copper-nickel alloys are preferred in machinery exposed to corrosive environments, such as marine applications. Beryllium copper alloys, known for high strength and electrical conductivity, are utilized in precision components like springs and electrical connectors.

Aluminium bronze, a copper-aluminium alloy, contributes to machinery components such as gears and bearings with its excellent wear resistance and strength.

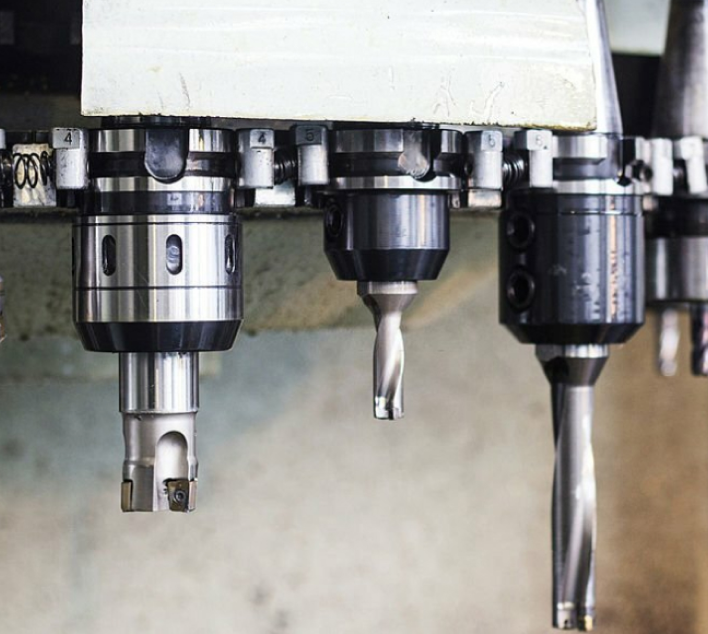

These copper alloys play a vital role in creating durable, efficient, and corrosion resistant components that form the backbone of machinery across various industries. Our Engineering team works with various suppliers to supply highly engineered products & tools of Copper Nickel Alloys & other Copper / Brass alloys which are used in the aerospace and transport industry.